-

SPONSORED

-

SPONSORED

-

Die/Mold

Micromachining Powder Metal on a VMC

By refining its micromachining process for powder metal tool steels, this shop has reduced production costs, lead times and secondary bench work for complex tooling components.

Read MoreMold Shop Finds Tool Performance Outweighs Price

This moldmaker sought to reduce costs to compete with low-cost overseas manufacturers. While purchasing relatively expensive, high-performance tools might seem counterintuitive, resulting improvements in cycle time and tool life more than made up the difference.

Read MoreHow Cameras Improve Capacity

Web cameras provide an inexpensive way to bring remote processes together, and to improve timing and confidence in unattended machining.

Read MoreThe Case for Software-as-a-Service ERP

The owner of a die manufacturing business describes why he prefers to subscribe to ERP software rather than buying it.

Read MoreVideo: Hard Pocket Milling

Relieved end mills and pre-machining of corners are two important considerations for accurate pocket machining in hard steel.

WatchIndexable Mills Speed Cavity Cutting

Ballnose mills are a common choice for hogging out cavities on molds and form dies. However, these three shops have realized significantly faster cavity milling by switching to Ingersoll’s Chip Surfer modular tooling system, which features a cylindrical shape that keeps more of the tool engaged in the cut.

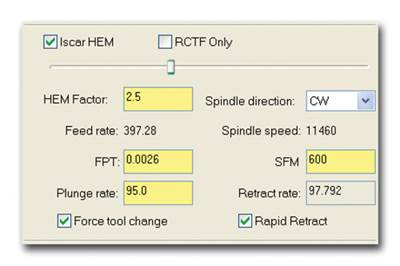

Read MoreSoftware/Tooling Partnership Promises Easier HSM

High-efficiency parameters are calculated automatically—partly using a slider that lets the programmer set the level of aggressiveness.

Read MoreFind Your Speed Outside of Machining

This short-lead-time mold shop achieves its most significant time savings by looking outside the machining cycle. However, one of those elements outside the cycle—palletized setup—ultimately led to cycle time savings via five-axis machining.

Read MoreVideo: Minimizing Mistakes with Laser Scanning ¸ßĹâÂĘÁůşĎ˛Ę

Die Tech & Engineering uses its scanning to ¸ßĹâÂĘÁůşĎ˛Ę to avoid errors by inspecting electrodes prior to EDM.

WatchMilling with Air

... not to mention grinding with air. Thanks to high speed spindles powered by shop air, this job shop expands the work its VMCs can do.

Watch