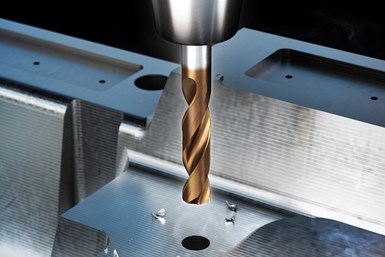

YG-1's Dream Drills Pro Optimized for Steel, Cast Iron

The Dream Drills Pro tools are made with micrograin carbide for core strength and longer tool life, and feature the company’s wave-shaped cutting edge to reduce cutting forces.

Share

YG-1 has beefed up its Dream Drills line-up with the new Dream Drills Pro line, which is optimized for machining in steel and cast iron. According to the company, the main advantages of these tools are increased cutting speeds and tool life.

The Dream Drills Pro tools are made with micrograin carbide for core strength and longer tool life. They also feature the company’s wave-shaped cutting edge to reduce cutting forces, and a wide-flute design optimized for faster, reliable chip evacuation. A self-centering 140-degree point angle reduces torque and extends tool life.

YG-1’s silicon-based, nano-layered Z-Coating technology gives cutting edges high hardness and heat resistance to improve tool life, while producing good surface finishes and a high number of parts per tool. The tools come in drilling depths of 3×D to 5×D.

Related Content

-

Chuck Jaws Achieve 77% Weight Reduction Through 3D Printing

Alpha Precision Group (APG) has developed an innovative workholding design for faster spindle speeds through sinter-based additive manufacturing.

-

Lean Approach to Automated Machine Tending Delivers Quicker Paths to Success

Almost any shop can automate at least some of its production, even in low-volume, high-mix applications. The key to getting started is finding the simplest solutions that fit your requirements. It helps to work with an automation partner that understands your needs.

-

Toolpath Improves Chip Management for Swiss-Type Lathes

This simple change to a Swiss-type turning machine’s toolpath can dramatically improve its ability to manage chips.