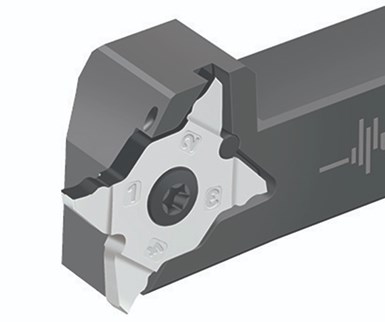

Walter USA's G3051-P Arranges Inserts for Efficient Grooving Along Shoulders

Walter USA’s G3051-P grooving system, designed for grooving along shoulders, uses MX22-2L/R indexable inserts inclined by 3 degrees in the insert pocket.

Share

Walter USA’s G3051-P grooving system uses MX22-2L/R indexable inserts inclined by 3 degrees to enable deep grooving operations along the shoulder. The four-edged MX inserts are available with Walter’s GD8 and VG8 geometries.

The GD8 geometry was developed for grooving along shoulders and grooving large diameters without interference of the insert with the finished workpiece. The VG8 geometry was designed for finishing operations behind a collar. The company says that its narrow shape reduces space requirements and saves material in mass production when compared to V-style ISO turning inserts.

The G3051-P grooving system can be used on CNC lathes and multi-spindle machines as well as automatic lathes. These holders, available in shank sizes of 0.625" to 1.0" and 12 to 25 mm, are designed with Walter’s precision cooling feature. The holders enable cutting depths ranging to 0.197" (5 mm), with insert widths ranging from 0.059" 0.118" (1.5 to 3 mm). The technology is particularly suited to high-volume production of smaller components, such as camshafts in the automotive industry and precision parts in the medical device industry.

The MX inserts’ large contact surfaces and dowel pin location contribute to stability, precision and indexing accuracy. The tangential arrangement of the grooving inserts is said to provide flatness and promote good surface quality.

Related Content

-

Shoulder Milling Cuts Racing Part's Cycle Time By Over 50%

Pairing a shoulder mill with a five-axis machine has cut costs and cycle times for one of TTI Machine’s parts, enabling it to support a niche racing community.

-

Medical Shop Performs Lights-Out Production in Five-Axes

Moving to five-axis machining enabled this shop to dramatically reduce setup time and increase lights-out capacity, but success relied on the right combination of workholding and automation.

-

Parts and Programs: Setup for Success

Tips for program and work setups that can simplify adjustments and troubleshooting.