Shopfloor Software Simplifies On-Control Programming

ModuleWorks offers its Next Generation Shopfloor Programming, designed to enable machine tool operators to build, simulate and run NC programs without G-code expertise.

Share

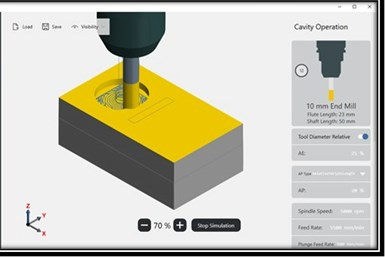

ModuleWorks’ Next Generation Shopfloor Programming (NGSP) software is designed to enable machine tool builders and CNC manufacturers to incorporate automated touchscreen programming into their proprietary on-control solutions.

The software was built on the ModuleWorks toolpath calculation and simulation technology and is integrated directly into the CNC. The NGSP is designed to enable machine tool operators to quickly build, simulate and run NC programs without in-depth knowledge of G-code programming. Because it is embedded in the control, NGSP has access to the tool library and physical parameters of the individual machine tool. This enables it to apply automatic decision-making to guide operators through the setup procedure and assist with tool selection, machining strategy and optimal cutting parameters for each job.

NGSP takes a 3D CAD model as input and displays the target workpiece and initial stock geometry on the CNC screen. Human-assisted feature detection identifies geometries such as channels, pockets and holes, and an initial tool path is calculated and shown on the model. The system guides users through the programming sequence and each operation removes part of the stock all the way to the roughing and finishing cycles. Built-in intelligence analyzes the geometry together with the required machining strategy and automatically recommends the appropriate tool and cutting parameters. Touching an operation block at any time opens menus to adjust parameters and select different tools and machining strategies. The tool path instantly updates each time a new setting is selected. In benchmark tests conducted by ModuleWorks, the company says programming a sample part with NGSP was 70% faster than with a conventional conversational programming system.

Related Content

-

2 Secondary Coordinate Systems You Should Know

Coordinate systems tell a CNC machine where to position the cutting tool during the program’s execution for any purpose that requires the cutting tool to move.

-

4 Commonly Misapplied CNC Features

Misapplication of these important CNC features will result in wasted time, wasted or duplicated effort and/or wasted material.

-

From Tradition to Transformation: Century-Old Manual Machine Shop Adds CNCs

After 122 years of working with manual mills and lathes, this fifth-generation shop acquired assets of a local CNC machining business and hired the owner. Here’s how it’s going a year later.

.JPG;width=70;height=70;mode=crop)