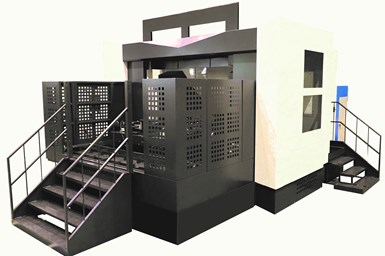

Niigata Engineers HN80E-5X for Maximum Rigidity

Niigata’s HN80E-5X Five-Axis Horizontal Machining Center features a heavy-duty construction that improves rigidity and part accuracy.

Share

The HN80E-5X Five-Axis Horizontal Machining Center is the latest addition to Niigata Machine Techno USA Inc.’s heavy-duty HN-5X Series. The HN80E-5X features an impressive 49.2” of travel in the X-axis, 48.4” in Y and 47.2” in Z, and allows a maximum workpiece diameter of 49.2”, height of 39.4” and weight of 3,300 pounds. For increased rigidity, stability and accuracy, the HN80E-5X incorporates the solid cast iron X and Z base of Niigata’s HN100D-II Heavy Duty Boxway Horizontal Machining Center.

The simultaneous five-axis machining of the HN80E-5X improves cycle times and machined surfaces of complicated and 3D curved components. A quick and easy five-axis compensation function ensures high accuracy over extended periods. Five-face machining reduces the number of setups and simplifies fixtures for reduced changeover time. A servo motor drives the tool magazine for fast and reliable indexing.

As with all HN-5X machines, the guide ways of the HN80E-5X consist of a combination of hardened and ground hand-scraped turcite for long life, stability and vibration damping. The cross section of the rectangular guide ways is thick and wide for maximum machine rigidity. Niigata’s unique bifurcated bell-shaped column further contributes to rigidity and metal cutting efficiency.

The High Load Type Roller BRG and a Double-Lead Worm Gear System for low frequency machining support both ends of Niigata’s heavy-duty five-axis trunnion table. For consistent long-life dynamic machine accuracy, the HN80E-5X is equipped with an optical-scale feedback system (on X, Y and Z axes) and an inductive-scale feedback system (on the A and B axes).

A high-torque, heavy-duty spindle complements the rigid machine frame. The spindle head stock consists of mono-cast castings for more powerful milling and greater accuracy than bolt-together type spindle heads.

The HN80E-5X comes equipped with the FANUC 30iM controller. A variety of five-axis machining support software is available.

Related Content

-

5 Tips for Running a Profitable Aerospace Shop

Aerospace machining is a demanding and competitive sector of manufacturing, but this shop demonstrates five ways to find aerospace success.

-

How to Mitigate Chatter to Boost Machining Rates

There are usually better solutions to chatter than just reducing the feed rate. Through vibration analysis, the chatter problem can be solved, enabling much higher metal removal rates, better quality and longer tool life.

-

6 Machine Shop Essentials to Stay Competitive

If you want to streamline production and be competitive in the industry, you will need far more than a standard three-axis CNC mill or two-axis CNC lathe and a few measuring tools.