Esprit CAM Software Integrates with Mazak's Smooth AI CNC

This development is an outgrowth of a collaborative partnership between DP Technology and Mazak Japan.

Share

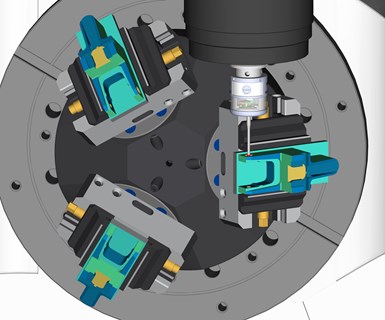

Esprit by DP Technology has announced extended support for Mazak’s Smooth AI CNC. Esprit produces optimized G-code programs, performs program optimization and provides machine simulation for Mazak’s entire line of machine tools. This extended support for Mazak’s Smooth AI CNCs now includes the ability to use Esprit’s digital twin capabilities from within the CNC. This development is an outgrowth of a collaborative partnership between DP Technology and Mazak Japan.

With this extended support, Esprit project data is thus synchronized with the Smooth AI CNC. The synchronized project data includes the part and stock models, workholding, tooling, work offsets, tool offsets and G-code program. With the synchronization between ESPRIT CAM and Mazak Smooth Ai, users can now preview the entire machining process virtually on the CNC — using the ESPRIT digital twin — before executing the program on the machine. As a result, manual data input is eliminated, and the machine operator is offered greater assurance of the machining process, the company says.

Related Content

-

How this Job Shop Grew Capacity Without Expanding Footprint

This shop relies on digital solutions to grow their manufacturing business. With this approach, W.A. Pfeiffer has achieved seamless end-to-end connectivity, shorter lead times and increased throughput.

-

Building A Powerful Bridge from the CAM Programmer to the Shop Floor Operator

SolidCAM for Operators provides a powerful bridge from CAM programming to the shop floor to best streamline the machine shop process with its CAM part simulation. It provides a clear picture to the operator for setup and prove-out, enables minor G-Code changes and avoids crashes, broken tools and scrapped parts.

-

Bringing Machining In-House to Keep up With Demand for Offroading Parts

To meet demand increases for its Ford offroad industry components, supplier RPG Offroad brought its machining processes in-house, saving the company nearly $50,000 per month. Here’s how its choice of integrated CAD/CAM software made it happen.