Cylindrical Grinding Machine Tour Launches

United Grinding recently introduced its Studer S11 small-parts production grinding machine to the North American market on the USS Yorktown. You’ll soon be able to see it, too, as it embarks on an eight-city tour, which started Feb. 19.

Share

The cam-actuated system shown in this video is one alternative for automated workpiece installation/removal on the new S11 cylindrical grinding machine. Note the in-process gaging capability being demonstrated, too.

I’m often introduced to new machining equipment at trade shows or company tech centers. Last week, unveiled its high-production cylindrical grinding machine for small parts to members of the press and UG distributors at its “Mini Motion” event held on the USS Yorktown aircraft carrier docked in Mount Pleasant, S.C.

In an effort to make it easier for busy manufacturers also to see the machine in action, the company is bringing it to them via a tour that includes stops in eight key areas across the United States as well as Canada and Mexico (tour dates and cities are listed below). UG engineers will be available at each stop to answer questions about the machine and the applications it’s geared toward.

The S11 occupies only 19.4 square feet of floor space but still includes a large 19.7-inch-diameter (500-mm) wheel.

It’s important to note that the S11 was not developed to be a universal-type grinding machine. Instead, it was specifically designed for automated, high-volume production of small, precision parts as long as 7.87 inches. The machine weights approximately 5,000 pounds and features a Granitan mineral-casting bed that offers good vibration damping qualities. It accommodates a 19.7-inch-diameter (500 mm) wheel and is available with the wheelhead plunge angle set at 0 or 20 degrees. It can also be set up to perform high-speed peel-grinding operations. Like other Studer cylindrical grinding machine designs, the X and Z axes are part of a self-contained cross-slide unit. Both axes have linear guideways mounted on roller bearings.

The S11 features a streamlined designed without unneeded options and uses no hydraulics. Instead, component actuation is performed electrically or pneumatically. Compact size with a floorspace area just over 19.4 square feet is combined with easy access for maintenance and setup. The main door offers three opening stages. Stage one opens upwards minimally and is intended for quick manual loading or a brief check of the workpiece. For stage two, the door opens a bit more so all table-mounted accessories are accessible from the top. Stage three enables a lower front panel to be dropped down to make the front fully accessible during set ups.

The machine is available in a range of automation configurations, and users should consult with UG representatives to determine the configuration that’s best-suited for their application. One is shown in the video above, in which a simple but effective cam system is used to remove and install workpieces from the chuck. StuderWinFocus software was developed for this machine to enable pictogram step-by-step programming, and the Siemens Sinumeric 840D SL control with touchscreen interface has a tablet look to it.

Here’s a list of cities and dates for the S11 North American tour. The machine will be accompanied by the Walter Helitronic Mini-Automation system that combines a five-axis universal grinding machine with robot loader.

• Feb. 19-20—Greer, S.C.

• Feb. 26-27—Rochester, N.Y.

• Mar. 5-6—Brecksville, Ohio

• Mar. 12-13—Livonia, Mich.

• Mar. 26-27—Itasca, Ill.

• April 8-9—Woodbridge, Ontario, Canada

• April 22-23—Los Alamitos, Calif.

• Spring 2014—Queretaro, Mexico

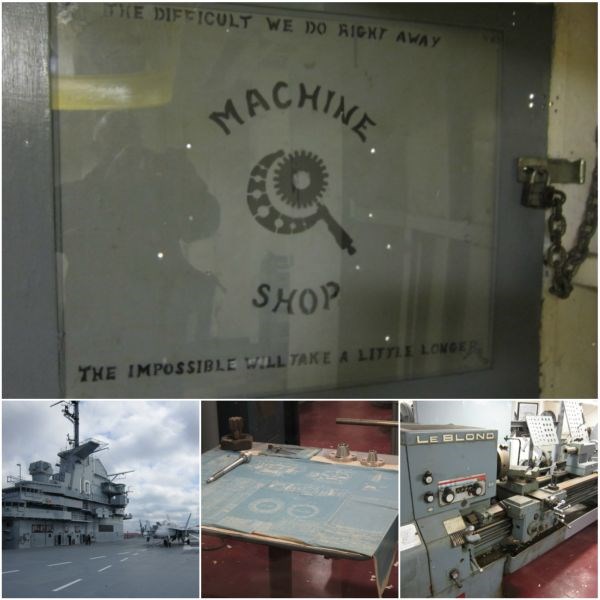

The Mini-Motion event was held on the USS Yorktown, which was appropriate given the journey the S11 machine is about to embark on. While touring the USS Yorktown, I was able to check out the aircraft carrier’s machine shop. Most machines there are still functional, and I appreciated the sign at the shop’s entrance.

Related Content

High RPM Spindles: 5 Advantages for 5-axis CNC Machines

Explore five crucial ways equipping 5-axis CNC machines with Air Turbine Spindles® can achieve the speeds necessary to overcome manufacturing challenges.

Read MoreInside a CNC-Machined Gothic Monastery in Wyoming

An inside look into the Carmelite Monks of Wyoming, who are combining centuries-old Gothic architectural principles with modern CNC machining to build a monastery in the mountains of Wyoming.

Read MoreLean Approach to Automated Machine Tending Delivers Quicker Paths to Success

Almost any shop can automate at least some of its production, even in low-volume, high-mix applications. The key to getting started is finding the simplest solutions that fit your requirements. It helps to work with an automation partner that understands your needs.

Read More5 Tips for Running a Profitable Aerospace Shop

Aerospace machining is a demanding and competitive sector of manufacturing, but this shop demonstrates five ways to find aerospace success.

Read MoreRead Next

AMRs Are Moving Into Manufacturing: 4 Considerations for Implementation

AMRs can provide a flexible, easy-to-use automation platform so long as manufacturers choose a suitable task and prepare their facilities.

Read MoreMachine Shop MBA

Making Chips and ¸ßĹâÂĘÁůşĎ˛Ę are teaming up for a new podcast series called Machine Shop MBA—designed to help manufacturers measure their success against the industry’s best. Through the lens of the Top Shops benchmarking program, the series explores the KPIs that set high-performing shops apart, from machine utilization and first-pass yield to employee engagement and revenue per employee.

Read More