Providing Consistent Tool Engagement in Five Axes

BobCAD-CAM says it is the first to provide a consistent tool-engagement-angle toolpath strategy for two through five-axis operations.

Share

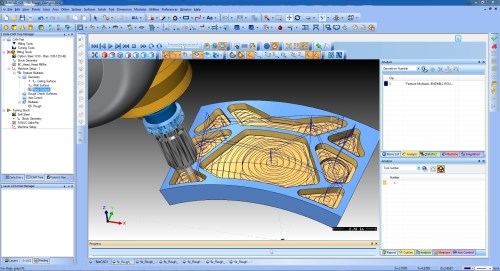

The Adaptive Roughing consistent-tool-engagement-angle tool path is well-suited for features such as this pocket that follows the contour of a cylinder.

is a software developer that has offered affordable, intuitive CAM packages for two- and three-axis machining applications for nearly 30 years. The company recently released its new Version 25 four- and five-axis mill software packages that enable it to offer a single programming platform for an increasing base of customers that are integrating higher-end equipment.

One way users can benefit from these packages is the ability to perform four- and five-axis simultaneous roughing operations. In fact, a new multi-axis tool path available in the company’s four-and five-axis packages makes such simultaneous, multi-axis roughing routines even more efficient. Adaptive Roughing applies the concept of consistent tool engagement angle that previously has been available only for two- and three-axis operations to four- and five-axis simultaneous movements. The company says it is the first to provide a consistent tool-engagement-angle toolpath strategy for two through five-axis operations.

Related Content

-

6 Machine Shop Essentials to Stay Competitive

If you want to streamline production and be competitive in the industry, you will need far more than a standard three-axis CNC mill or two-axis CNC lathe and a few measuring tools.

-

5 Tips for Running a Profitable Aerospace Shop

Aerospace machining is a demanding and competitive sector of manufacturing, but this shop demonstrates five ways to find aerospace success.

-

Can ChatGPT Create Usable G-Code Programs?

Since its debut in late 2022, ChatGPT has been used in many situations, from writing stories to writing code, including G-code. But is it useful to shops? We asked a CAM expert for his thoughts.