Get the Handbook on MQL

A free handbook from Unist explains the benefits of minimum quantity lubrication and offers advice for those interested in moving away from conventional flood coolants.

Share

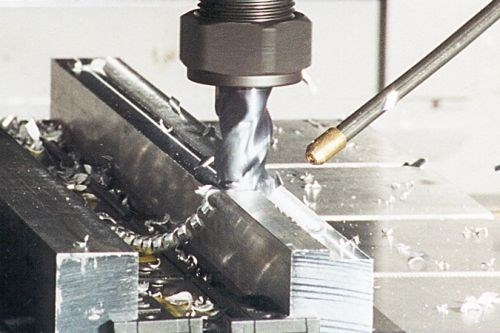

Minimum quantity lubrication (MQL) is used more in Europe than here in the States due to stricter environmental regulations across the pond. However, MQL has a proven track record in working just as well as, or better than, traditional flood coolants for certain applications. Plus, shops don’t have to deal with negative consequences like health hazards, disposal costs and pricey circulation equipment. If you’re interested in learning more about MQL, consider signing up to receive the “MQL Handbook” offered by , the Grand Rapids, Michigan manufacturer of MQL systems for metalworking applications.

The handbook explains how MQL differs from conventional coolant methods, how it works, what equipment is needed, how to develop an MQL process and what fluids work best for it. Sign up to receive the handbook .

Related Content

-

LNS Chipblaster Provides High-Pressure Coolant Using CNC Interface

The Chipblaster S Series is designed to precisely apply high-pressure coolant where and when required.

-

New Coolant Designed for Automotive Parts Production

Choosing the right coolant is critical for productivity, economic efficiency and machining quality.

-

Marubeni Citizen-Cincom Accessories Provide Faster Cycle Times

IMTS 2024: Marubeni Citizen-Cincom is showcasing a range of machining accessories designed to work intuitively with Citizen machines.