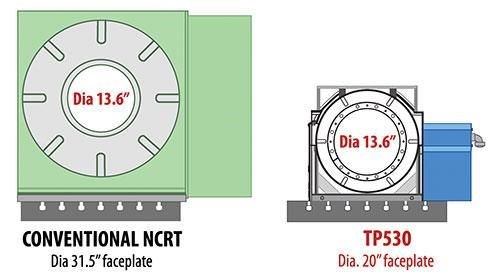

Enabling Small Machines to Produce Big Parts

Well-suited for oilfield work, this compact rotary table has a through-hole diameter of 13.6 inches, which has previously been available only with rotary tables having a much larger face plate.

Share

This rotary table has a through-hole diameter of 13.6 inches, which has previously been available only with rotary tables having a 31.5-inch face plate. It is also 484 pounds lighter.

notes that the size of cylindrical oilfield components are getting larger. This typically would mean that shops with limited size capacity for its machines would have to purchase a larger machine not so much to accommodate the part, but the big NC rotary table. That’s why the TP530 was developed to deliver the requisite through-hole diameter in a more compact overall size than comparable rotary tables so this type of work can be performed on smaller machines. Learn more.

Related Content

-

How to Mitigate Chatter to Boost Machining Rates

There are usually better solutions to chatter than just reducing the feed rate. Through vibration analysis, the chatter problem can be solved, enabling much higher metal removal rates, better quality and longer tool life.

-

Chuck Jaws Achieve 77% Weight Reduction Through 3D Printing

Alpha Precision Group (APG) has developed an innovative workholding design for faster spindle speeds through sinter-based additive manufacturing.

-

Briquetting Manufacturer Tools Up for Faster Turnaround Times

To cut out laborious manual processes like hand-grinding, this briquette manufacturer revamped its machining and cutting tool arsenal for faster production.