CAM to CAM Data Exchange With STEP-NC

CAD to CAD data exchange has been possible for decades, but CAM to CAM data exchange is just now emerging. An open meeting sponsored by OMAC on June 24-25, 2013 will test and demonstrate prototype translators to facilitate data exchange using the STEP-NC standard.

Share

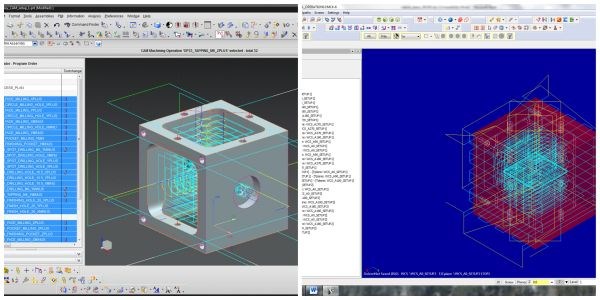

CAD systems have long been able to exchange part geometry files by translating the data into a vendor-neutral format. Translators using the STEP-NC standard are now enabling CAM systems to exchange manufacturing data such as CNC machining programs. These translators are expected to result in new levels of machine tool interoperability.

An supported by on June 24-25, 2013 will test and demonstrate prototype translators to facilitate data exchange using the STEP-NC standard. The meeting will be held at the Commonwealth Center for Advanced Manufacturing in the Richmond, Virginia, area. OMAC (Organization for Machine Automation and Control) is an industry consortium created to help end users, technology providers, government institutions, academia and original equipment manufacturers (OEMs) work together to find innovative ways to improve production operations.

The meeting will review tests and demonstrations of CAM to CAM data exchanges for Mastercam, Siemens NX and CATIA V5. Pilot projects to develop the business advantages of these translators to facilitate a more accurate and timely job quoting process, on-machine part inspection and acceptance, improved cutting tool selection and earlier simulation/verification of manufacturing processes will also be announced. The cutting tool pilot is likely to be the first to be deployed. In it, users will send operation descriptions to tooling bendors and receive back tool recommendations with process descriptions that minimize the total cost of tooling.

The concept behind STandard for Exchange of Product model data –Numerical Control (STEP-NC) is to use geometric constructs representing part features and their associated characteristics such as dimensional tolerances to define device-independent tool paths. STEP-NC is intended to enable manufacturing organizations to seamlessly share machining and measurement information between machines and over the Internet. STEP-NC replaces machine input based on M and G codes with an associative language that connects the CAD data used to determine the machining requirements for an operation with the CAM process data that solves those requirements.

Related Content

-

How this Job Shop Grew Capacity Without Expanding Footprint

This shop relies on digital solutions to grow their manufacturing business. With this approach, W.A. Pfeiffer has achieved seamless end-to-end connectivity, shorter lead times and increased throughput.

-

4 Commonly Misapplied CNC Features

Misapplication of these important CNC features will result in wasted time, wasted or duplicated effort and/or wasted material.

-

Can AI Replace Programmers? Writers Face a Similar Question

The answer is the same in both cases. Artificial intelligence performs sophisticated tasks, but falls short of delivering on the fullness of what the work entails.