An Insider’s Look at MTConnect-Enabled Applications

A new whitepaper from the MTConnect Institute is designed to help software developers create client applications that take advantage of the valuable data generated by manufacturing equipment but previously more difficult to access.

Share

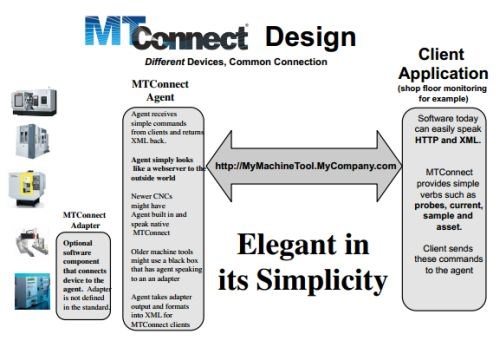

The whitepaper photo above depicts the Three As of MTConnect:

agents, adapters and applications.

MTConnect is an open and royalty-free standard for manufacturing that is connecting manufacturing equipment with applications by using proven Internet protocols. But MTConnect is not an application. Applications are software products designed to use data in the specified MTConnect format for such purposes as machine monitoring, energy usage management, cutting tool control and many others. A new whitepaper from the MTConnect Institute is designed to help software developers create applications that take advantage of the valuable data generated by manufacturing equipment that was more difficult to access before MTConnect appeared.

Although the content of this whitepaper is rather technical and thorough, it is readable and well-organized, so any shop interested in what MTConnect can do to improve operations ought to check it out for its insights into the inner workings of useful applications. The paper includes an overview of MTConnect, definitions of key terms, illustrations of essential concepts and basic outlines of application architecture. The whitepaper is available here.

Related Content

-

Swiss-Type Control Uses CNC Data to Improve Efficiency

Advanced controls for Swiss-type CNC lathes uses machine data to prevent tool collisions, saving setup time and scrap costs.

-

How this Job Shop Grew Capacity Without Expanding Footprint

This shop relies on digital solutions to grow their manufacturing business. With this approach, W.A. Pfeiffer has achieved seamless end-to-end connectivity, shorter lead times and increased throughput.

-

Protecting Your Automation Investments

Shops need to look at their people, processes and technology to get the most of out their automation systems.